MOST TRUSTED

OVER 6K SATISFIED CUSTOMERS...

150+ (5) STAR REVIEWS

What is Epoxy!?

If you are not already familiar with what epoxy is or the different uses of Epoxy floor finishes, by the end of this you will be.

Feel free to learn more below or if you wish to skip the wait, and have us do this for you, Click above to book a free estimate online or call us today!

Peoria Epoxy Floors: Modern Flooring Solutions

Introduction to Epoxy Flooring Peoria, Illinois

Epoxy flooring has become one of the most popular surface solutions for Central Illinois residential, commercial, and industrial spaces. Known for its durability, seamless appearance, chemical resistance, and modern aesthetic, epoxy flooring offers a long-lasting alternative to traditional flooring systems such as tile, vinyl, concrete sealers, and paint coatings.

At its core, epoxy flooring Peoria is created by combining epoxy resin with a hardening agent, forming a rigid plastic material that bonds strongly to a prepared substrate—most commonly concrete. Once cured, epoxy floors create a smooth, durable surface that can withstand heavy traffic, mechanical stress, moisture, and chemical exposure.

Over the years, epoxy flooring has evolved from a purely industrial solution to a highly customizable design option suitable for homes, retail spaces, offices, healthcare facilities, and more. With a wide range of colors, textures, and finishes available, epoxy floors can be both functional and visually striking.

This will introduce you to everything you need to know about epoxy floors, including how they work, their benefits, types, applications, maintenance, limitations, and long-term value.

What Is Peoria Epoxy Flooring?

Epoxy flooring is a surface system made by applying multiple layers of epoxy-based materials onto a prepared floor, typically concrete. The chemical reaction between resin and hardener creates a thermoset polymer that is extremely strong, rigid, and resistant to wear.

Unlike traditional floor coatings or paints that simply dry, epoxy chemically cures, forming a bond that integrates with the substrate. This creates a seamless, non-porous surface that resists damage from impacts, stains, chemicals, and moisture.

Epoxy Flooring Peoria systems can vary in thickness, texture, and composition depending on the intended use. Some systems are thin and decorative, while others are thick, reinforced, and engineered for heavy industrial environments.

Key Components of Epoxy Flooring

Epoxy Resin

The resin is the main body of the epoxy system. It provides adhesion, strength, and chemical resistance.

Hardener

The hardener triggers the chemical curing process. When mixed with resin, it causes the epoxy to harden and bond to the surface.

Pigments and Additives

Color pigments, decorative flakes, metallic powders, and aggregates can be added for appearance and performance enhancements.

Sealers and Topcoats

Many epoxy floors include protective topcoats to improve UV resistance, slip resistance, or gloss retention.

Benefits of Epoxy Flooring

Exceptional Durability

Peoria epoxy floors are designed to withstand heavy loads, foot traffic, machinery, and impacts without cracking or peeling when properly installed.

Seamless and Hygienic

The seamless nature of epoxy floors eliminates grout lines and joints, making them easy to clean and ideal for hygienic environments.

Chemical and Stain Resistance

Epoxy resists oil, grease, solvents, acids, and many cleaning chemicals, making it suitable for garages, laboratories, and industrial spaces.

Moisture Resistance

When properly installed, epoxy floors create a moisture-resistant barrier that helps protect concrete from water damage.

Aesthetic Versatility

Available in solid colors, metallic finishes, flake systems, and custom designs, epoxy floors can match nearly any style.

Long Lifespan

With proper care, epoxy floors can last 10–20 years or more, reducing long-term flooring replacement costs.

Improved Safety

Slip-resistant additives and high-visibility colors can enhance safety in work environments.

Common Applications of Epoxy Flooring Peoria

Residential Spaces

Epoxy floors are increasingly popular in homes due to their modern look and durability.

Garages

Basements

Laundry rooms

Workshops

Utility rooms

Homeowners value epoxy for its resistance to stains, ease of cleaning, and ability to transform dull concrete into an attractive surface.

Commercial Spaces

Epoxy flooring is widely used in commercial environments where aesthetics and performance are both important.

Retail stores

Showrooms

Offices

Restaurants

Hotels

Schools

Custom colors and branding elements can be incorporated to align with a company’s identity.

Industrial Facilities

Epoxy flooring originated in industrial settings and remains a top choice for demanding environments.

Warehouses

Manufacturing plants

Factories

Power plants

Distribution centers

Heavy-duty epoxy systems can support forklifts, machinery, and constant traffic.

Healthcare and Laboratories

Hygiene and chemical resistance make epoxy ideal for medical environments.

Hospitals

Clinics

Laboratories

Pharmaceutical facilities

Seamless surfaces reduce the risk of bacteria buildup and allow for aggressive cleaning.

Food and Beverage Facilities

Epoxy floors are commonly used in food-related spaces due to their durability and cleanability.

Commercial kitchens

Breweries

Food processing plants

Cold storage areas

Special formulations can handle temperature changes and moisture exposure.

Types of Epoxy Flooring Systems

Self-Leveling Epoxy Floors

Self-leveling epoxy spreads evenly across the surface, creating a smooth and seamless finish.

Best for:

Commercial spaces

Showrooms

Warehouses

Residential interiors

Epoxy Mortar Floors

Epoxy mortar systems are extremely durable and can repair damaged concrete while providing a high-strength surface.

Best for:

Industrial environments

Heavy machinery areas

Epoxy Flake Floors

Decorative flakes are broadcast into the epoxy to create a textured, multi-colored appearance.

Best for:

Garages

Locker rooms

Retail spaces

Metallic Epoxy Floors

Metallic pigments create a reflective, three-dimensional appearance with unique patterns.

Best for:

Showrooms

Lobbies

High-end residential spaces

Quartz-Filled Epoxy Floors

Quartz systems combine colored quartz granules with epoxy resin for durability and slip resistance.

Best for:

Healthcare facilities

Restrooms

Pool decks

Anti-Static Epoxy Floors

Designed to dissipate static electricity.

Best for:

Electronics manufacturing

Data centers

Laboratories

Epoxy Flooring vs Other Flooring Options

Epoxy vs Tile

Epoxy has no grout lines, making it easier to clean and more resistant to moisture penetration.

Epoxy vs Polished Concrete

Epoxy offers more color and design options, while polished concrete has a more natural appearance.

Epoxy vs Vinyl

Epoxy is more durable and chemical-resistant, while vinyl may be softer underfoot.

Epoxy vs Paint

Epoxy bonds chemically and lasts significantly longer than floor paint.

Design and Customization Options

Epoxy flooring offers extensive customization possibilities:

Solid colors

Custom color matching

Decorative flakes

Metallic swirls

High-gloss or matte finishes

Logos and patterns

Safety striping

This versatility allows epoxy floors to serve both functional and branding purposes.

Surface Preparation and Installation Overview

Successful epoxy flooring depends heavily on surface preparation. Concrete must be clean, dry, and properly profiled to ensure adhesion.

Typical installation stages include:

Surface cleaning

Repairing cracks or damage

Priming

Epoxy application

Decorative elements (if any)

Topcoat sealing

Curing time

Professional installation is recommended for best performance and longevity.

Curing and Drying Time

Epoxy floors cure through a chemical reaction rather than evaporation.

Light foot traffic: typically within 24 hours

Full cure: several days depending on system type

Heavy use: after full curing period

Curing times vary based on temperature, humidity, and product formulation.

Maintenance and Cleaning

Epoxy floors are low maintenance compared to many other flooring options.

Routine Maintenance

Sweeping or dust mopping

Damp mopping with mild cleaners

Prompt spill cleanup

Long-Term Care

Periodic reapplication of topcoat (if needed)

Avoiding abrasive tools

Using protective pads under heavy equipment

Proper maintenance helps preserve appearance and performance for many years.

Slip Resistance and Safety Considerations

While epoxy floors can be smooth, slip-resistant additives can be incorporated to improve traction.

Textured finishes

Aggregate additives

Matte topcoats

These features are especially important in wet or high-traffic areas.

Environmental and Sustainability Considerations

Modern epoxy systems can be formulated with:

Low VOC emissions

Long service life (reducing waste)

Improved indoor air quality

Because epoxy extends the lifespan of concrete floors, it can reduce the need for frequent replacement.

Limitations of Epoxy Flooring

While epoxy flooring has many advantages, it also has limitations:

Requires proper surface preparation

Can be sensitive to UV exposure without protective topcoats

Hard surface may feel less comfortable for long standing

Installation downtime during curing

Understanding these factors helps ensure epoxy is the right choice for a given space. If in fact you find yourself needing news walls, we also perform drywall and paint. If in fact you live in Bloomington and need Bloomington, Illinois Drywall Repair contact us for a free estimate.

Cost Considerations

The cost of epoxy flooring varies based on:

System type

Floor condition

Design complexity

Square footage

Location

Although epoxy may have a higher upfront cost than basic coatings, its long lifespan often makes it cost-effective over time.

Longevity and Performance Expectations

When properly installed and maintained, epoxy floors can last:

10–15 years in residential spaces

15–20+ years in commercial or industrial settings

Performance depends on usage, maintenance, and environmental conditions.

Why Choose Epoxy Flooring?

Epoxy flooring stands out as a high-performance, versatile, and visually appealing solution for a wide range of environments. Its durability, seamless nature, and customization options make it suitable for both practical and design-focused applications.

From garages and basements to hospitals and factories, epoxy floors provide a reliable surface that combines strength, safety, and style.

Peoria epoxy flooring is more than just a coating—it is a comprehensive flooring system designed to enhance durability, functionality, and appearance. With its resistance to wear, chemicals, and moisture, epoxy flooring offers long-term value across residential, commercial, and industrial settings.

As flooring technology continues to advance, epoxy remains a trusted and adaptable solution that meets the demands of modern spaces. Whether prioritizing performance, aesthetics, or hygiene, epoxy flooring delivers on all levels. Most importantly is looks!

Peoria, Il. Concrete Polishing

Concrete Polishing: A Modern Flooring Solution

Concrete polishing is a process that transforms ordinary concrete surfaces into smooth, durable, and visually appealing floors. Once considered purely industrial, polished concrete has become a popular flooring option for residential, commercial, and industrial spaces. Its strength, low maintenance, and modern appearance make it an attractive alternative to tile, wood, and carpet.

What Is Peoria Concrete Polishing?

Concrete polishing is a mechanical process that uses progressively finer diamond abrasives to grind and polish the surface of concrete. The goal is to create a smooth, glossy finish while improving the floor’s durability and resistance to wear. Unlike coatings or overlays, polished concrete uses the existing concrete slab, making it a long-lasting and environmentally friendly solution.

The process often includes the application of a chemical densifier, which penetrates the concrete and hardens it. This step increases surface strength and reduces dusting, a common issue with untreated concrete floors.

The Concrete Polishing Peoria Process

Concrete polishing typically follows several key steps:

Surface Preparation

The concrete is inspected for cracks, stains, or uneven areas. Any necessary repairs are completed before polishing begins.

Grinding

Heavy-duty diamond grinding tools are used to remove surface imperfections and expose the desired level of aggregate, if any.

Densifying

A liquid densifier is applied to harden the concrete and prepare it for polishing.

Polishing

Finer diamond abrasives are used to gradually polish the surface to the desired sheen, ranging from matte to high gloss.

Sealing or Guard Application

A protective sealer or guard may be applied to enhance stain resistance and longevity.

Benefits of Polished Concrete

Polished concrete offers numerous advantages over traditional flooring materials:

Durability: Polished concrete is extremely strong and resistant to heavy foot traffic, making it ideal for commercial and industrial settings.

Low Maintenance: Routine cleaning typically requires only dust mopping and occasional damp mopping.

Cost-Effective: Since it uses the existing concrete slab, material costs are lower than many flooring options.

Aesthetic Appeal: Polished concrete provides a sleek, modern look and can be customized with stains, dyes, or decorative scoring.

Eco-Friendly: Minimal materials are used, reducing waste and environmental impact.

Improved Light Reflection: The reflective surface enhances lighting efficiency, potentially lowering energy costs.

Common Applications

Polished concrete is widely used in various settings, including:

Retail stores and shopping centers

Warehouses and industrial facilities

Offices and commercial buildings

Restaurants and cafes

Residential homes, especially modern and minimalist designs

Its versatility allows it to fit both functional and decorative purposes.

Maintenance and Longevity

One of the greatest advantages of polished concrete is its longevity. When properly maintained, polished concrete floors can last for decades without needing replacement. Maintenance involves basic cleaning and occasional reapplication of protective treatments in high-traffic areas.

Peoria Concrete polishing is a practical and stylish flooring solution that combines durability, sustainability, and modern design. Its ability to withstand heavy use while maintaining an attractive appearance makes it suitable for a wide range of environments. As more property owners seek long-lasting and low-maintenance flooring options, polished concrete continues to grow in popularity as a smart investment for both residential and commercial applications. If you need concrete polishing or concrete sealing, contact us for a free estimate.

EPOXY

FLOORING PEORIA

MOST POPULAR INSTALLS

GARAGE

BASEMENT

HOME GYM

MAN CAVE

PLAY ROOM

LIVING SPACES

KITCHENS

PORCH & WALKWAYS

COMMERCIAL KITCHEN

LAB FLOOR

JOIN OVER 6,000...

SATISFIED CUSTOMERS

WITH A BRAND NEW COATING!!

HOMEOWNERS

BUSINESS OWNERS

HIRE US 🤝

3 STEP PROCESS

GET QUOTE

Have your project looked at in person or choose to send a photo, You will receive an estimate by email in 24 hrs.

GET COATED

Accept your quote and schedule your coating install at a time that works Best for you.

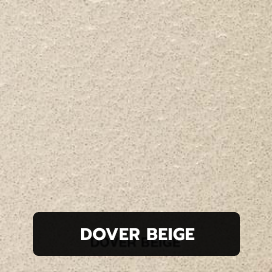

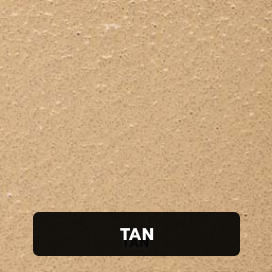

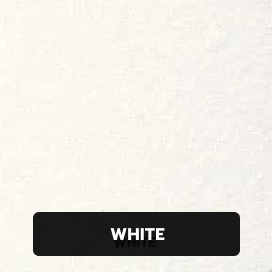

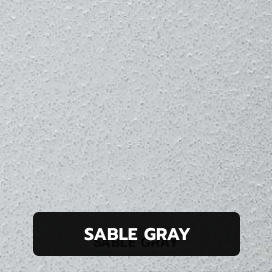

COLOR OPTIONS

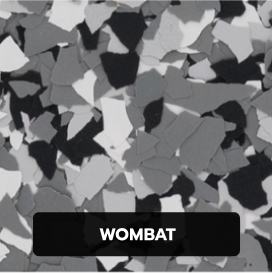

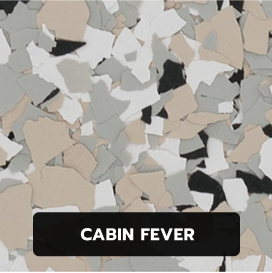

MOST POPULAR

BLENDS

Don't see a color you like?

Contact us for a custom blend.

PDPAE

Peoria Drywall

Paint & Epoxy

8101 N. University St.

Peoria, Illinois 61615

309-681-5500